- Venjakob

- Plant engineering

- Industry 4.0

Industry 4.0 with Venjakob

Achieve and finish more, with digital solutions

This is the age of digital solutions – and anyone who doesn’t use them yet, is sure to change that sooner or later. But when you start using digital solutions, you need them to be truly forward-looking concepts. Venjakob’s solutions are. We discovered the value of automation and digital solutions early on. This means we were part of the transformation of innovative information and communication technologies and helped shape it in our industrial environment. In short: From the very beginning, networking our system components was part of the solutions we offered and still offer to you, our customers. And it will stay that way in future, too. Be it through plant automation, robotics or process control technology.

Your partners for your future

For years, we at Venjakob have been developing solutions for digital plant engineering with the aim of networking individual systems. From process automation through predictive maintenance to machine learning, we will bring your value chain to the digital age. That is what makes Venjakob the right partner to support you throughout your projects for the future of your business.

Benefits

What are the benefits of IoT-capable networking in your plant? Just for instance:

- Flexible production

- Modular production lines

- Customer oriented solutions

- Efficient logistics

- Big data analytics

Digitalized, sustainable, controlled

We have the data and – if you want – the access to keep track of and maintain your plant wherever it is located. This benefits you. And your customers. And the environment. After all, it increases your safety and boosts your efficiency. Your customers get what you promised them, in the time and quality they expect. And the environment benefits, because we do away with unnecessary travel by using remote maintenance instead. So, in the end, this is great for absolutely everyone.

SMART, MODULAR AND INCREDIBLY EFFICIENT

- VEN PROFIT

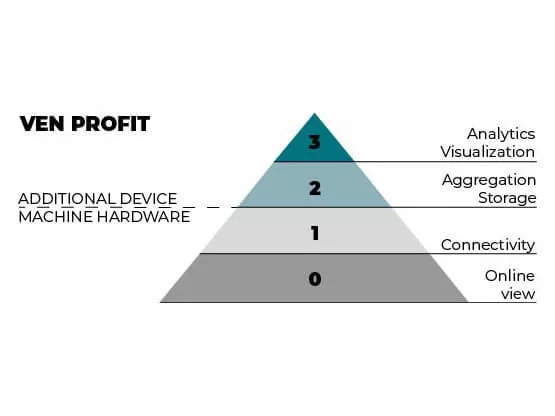

VEN PROFIT - that is the name of our smart software modules that collect and evaluate all relevant data of your entire production process via cloud-based databases. Tailor-made process data control supports efficient production of workpieces and creates a foundation for completely new business models and services at the same time. That's why our software has its name: VEN PROFIT.

And what does that mean for future-proofing your systems?

That’s easy to explain: We network all components of your complete coating line: Production and IT become one. If a machine produces different variants of a product, the workpieces themselves "inform" the machine how to process each of them. How does that work? The workpieces "carry" their own identifying information and exchange it with the system. This means different product variants can be produced in one production line thanks to Industry 4.0. It also means you can react quickly, individually and flexibly to short-term orders and changes in requirements. Make your production processes more flexible. And let us help you do so.

Interested? Then let's talk! About intelligent networking of your custom-designed Venjakob finishing system.