- Venjakob

- areas of application

- Steel coating

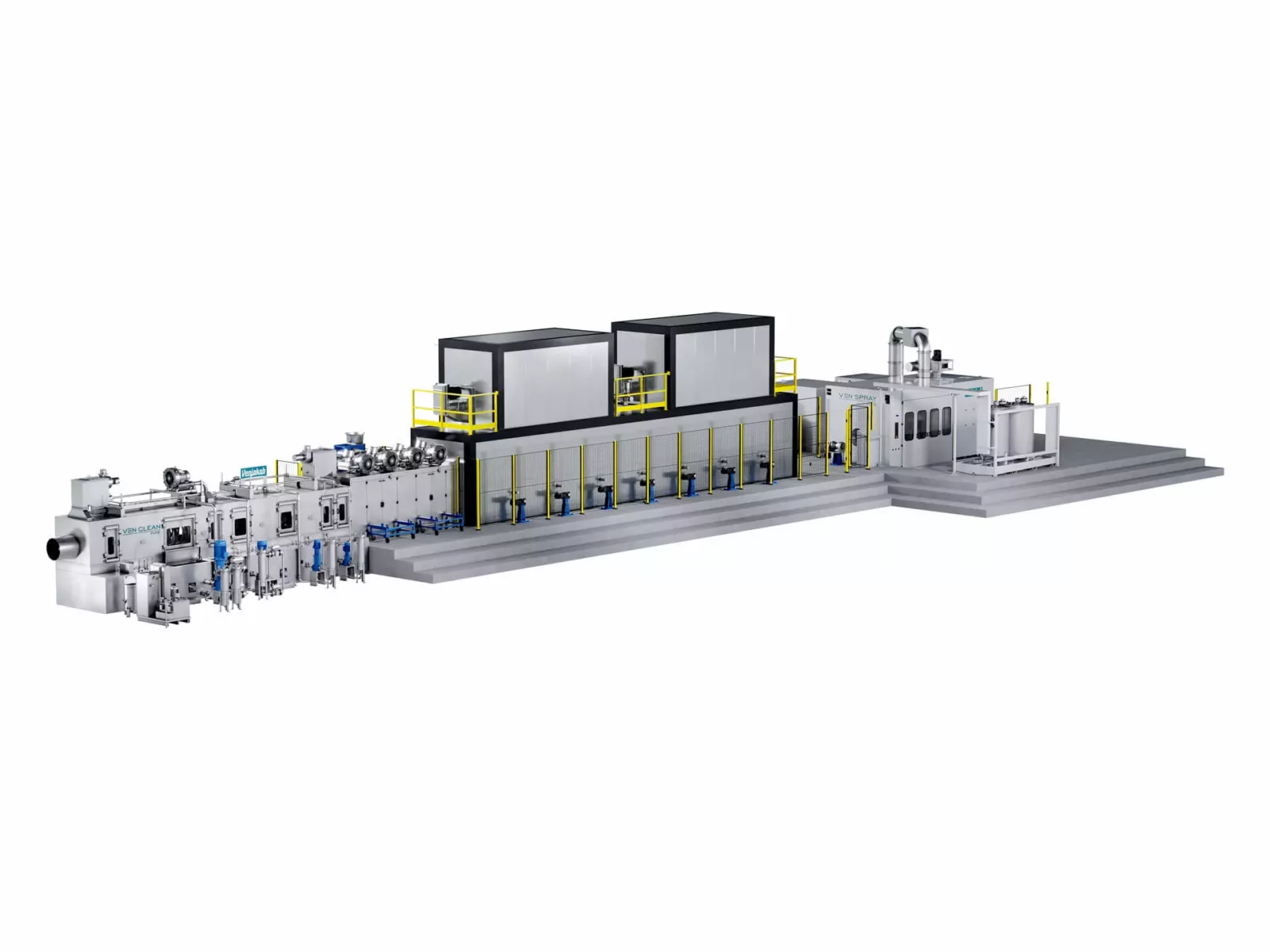

Steel coating with Venjakob

Coating systems for surface treatment of metal and steel

Steel – like metal in general – is a very special material and applying a coating to it requires extensive know-how. Its wide range of applications alone raises very general questions: How do you coat steel? Or: What coating processes are available? Are there different steel coatings? Aside from that, there are more detailed questions: What is a C3 coating? Why is it necessary – and when? At Venjakob, we are experts at these and all other questions concerning coating and finishing systems for surface treatment of metal and steel. And we don’t just know our way around coating, but around the entire process – from primer coating to intermediate coating to applying the finishing coat, with thorough cleaning and degreasing beforehand and final drying, conveyor technology and feeding included. That’s not some random claim, but a fact proven by the numerous success stories of a wide variety of applications. You can find some of them further down this page.

Functional or decorative coating for metal parts and steel components

Coating steel, coating metal – depending on where the metal parts or steel components are used, this is either a question of function, appearance or both. Corrosion protection is at the very top of the list of requirements. But often enough, it's not just about protecting the component in question from corrosion. It also has to look good. For instance, in automotive production. But no matter the component, they all have to be safe. Structural parts for aircraft – such as sheet metal parts – must withstand any risk of corrosion. In short: When it comes to metal and steel coating, expert knowledge is absolutely indispensable. Professional coating of metal components is a matter for experts. Through decades in the business, Venjakob has acquired unparalleled experience in designing and building plants for treating metal surfaces. We build customized coating systems for finishing metal surfaces and metallic workpieces. The equipment we develop is tailored precisely to your production conditions and will let you treat these surfaces efficiently and reliably.

Typical applications

In industry – for instance in sectors such as automotive, aerospace or industrial construction – steel and metal treatment is essential: Professional processing of metal in general and steel in particular permits the reliable coating of

- Screws

- Wheels

- Housings

- Forged parts

- Large sheets|plates

- Profile steel

- Pipes

Standards, corrosion protection, effect coatings and decorative coatings

The simplest solution: Taking into account all the essential factors of each application. And that brings us to the more complex answers. The essential factors are, after all, highly diverse. They are as diverse as the different applications themselves. For example, if you are looking for a suitable C3 coating, you can easily figure out that you’ll need at least two additional C categories beforehand and some after. These C categories describe the corrosiveness categories for components with air contact according to DIN EN ISO 12944-2. They classify corrosion exposure from C1 (insignificant) to C5-M (very severe exposure due to marine influences). Coating systems used to coat steel must be able to meet the requirements defined in the applicable standards. Our solutions do. For any product – no matter if it is used indoors or outdoors. But corrosion aside, Venjakob solutions stand out because they keep the entire steel coating process in mind – all steps, all materials, in every industry, for all customers and the market in which they operate. And corrosion protection is only one of the topics we focus on. We also offer excellent solutions for decorative and effect coatings, for top coats – in fact, for everything that permanently preserves the effect of color.

Corrosion protection through steel coating – an overview of the process steps

One reason to apply a coating to steel is corrosion protection. When metal or steel need to be coated, the following systems and processes are available: Conveyor technology for feeding, systems and processes for dust removal, degreasing and cleaning (for example by blasting), preheating of the workpieces if required, coating and finishing systems, and systems for discharge and removal. It is not always necessary to choose all procedures. We have provided a detailed description of the complete process for coating steel sheets and beams. In this description we focus on the three essential steps of cleaning, coating, drying.

Cleaning and degreasing of surfaces

Effective degreasing and cleaning of the steel surface is usually essential before coating. Venjakob offers various processes and technologies for degreasing and cleaning the surface. These remove loosely adhering contaminants and residual operating materials from previous processing steps from your workpieces.

Coating and finishing for effective corrosion protection

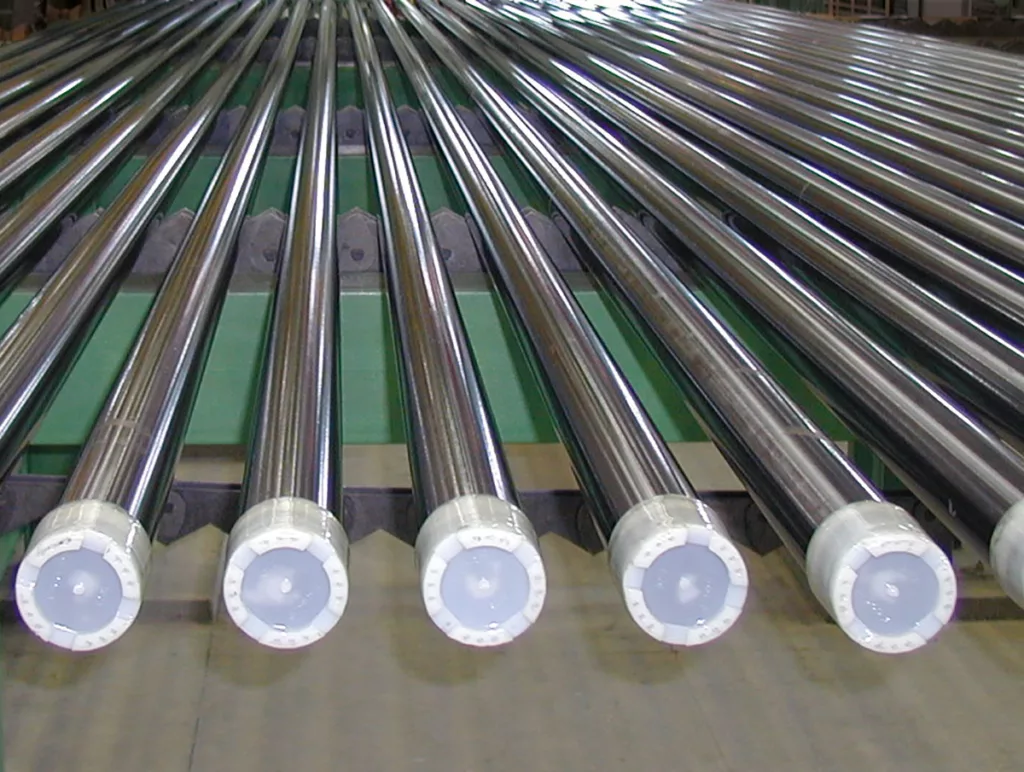

Venjakob offers a wide range of concepts for functional coatings. Especially when it comes to coating steel pipes with 100% UV coating, Venjakob has earned an excellent reputation in the market with its high-performance coating lines that include pipe cleaning and drying. Pipes to which temporary corrosion protection has been applied are protected directly and can immediately be strapped into bundles and transported further.

Drying and curing

After coating comes drying – and sometimes UV curing. This guarantees a high quality for the steel coating. Our processes, integrated directly into your process, guarantee that this step is highly efficient. We usually use the warm exhaust air from the preheating phase for this – and that’s not just smart and efficient, but energy-efficient.

Applications

The metal and steel processing industry requires excellent surface technology. Venjakob provides it. We don’t do off-the-shelf products. Instead, we provide unique solutions that are truly tailored to the specific requirements and applications. We develop your solution for you – from consulting and plant design through project planning and production to commissioning and plant visualization. Industry 4.0 included.

Pipes

Complete pipe coating lines including cleaning, labeling, coating and drying. Suitable for water-based, solvent-based and 100% UV coating materials. Tracking individual workpieces through codes is possible.

Wheels

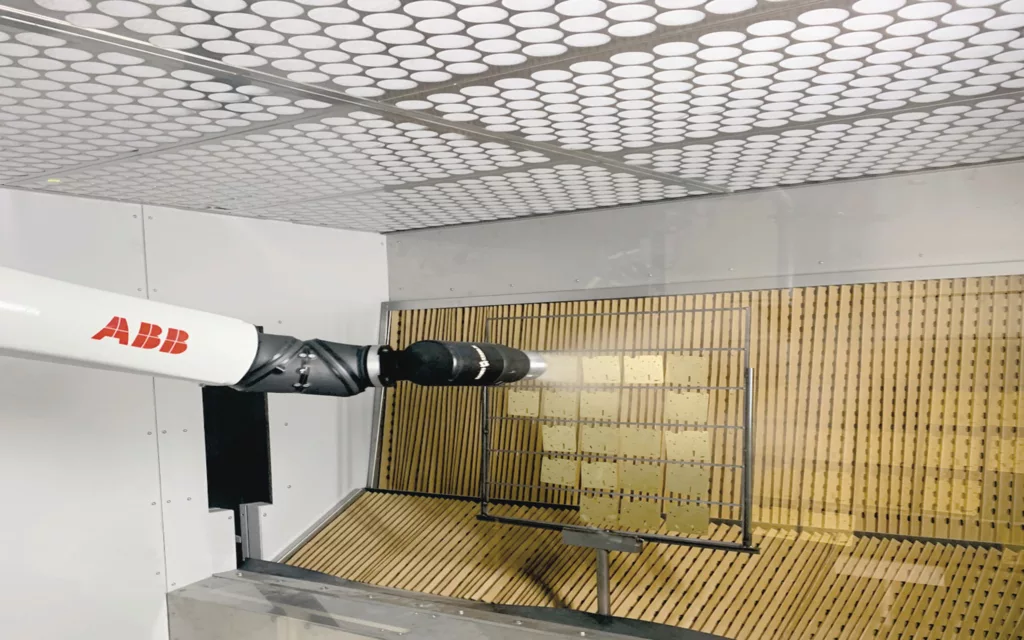

For wheels and rollers of all types, we at Venjakob supply efficient and flexible processes for reliable coating - for example, by means of rotary index table/robot systems or spindle chain conveyor system.

Steel sheets | Beams

Water-based coating systems and flatbed coating lines are most commonly used for the coating of steel sheets and beams. Coating is carried out in a continuous process, in which the material is separated beforehand if requested.

Housings

Engine, gearbox and cover housings place high demands on the coating process. In particular, proper handling of the housings plays a vital role. At Venjakob, we develop customized automation for you - with spindle chain conveyors, robot systems or a flatbed coating line.

Looking for a success story? We’ve got one for you

Trust is good, proof is better. We would like to show you three outstanding references, each of which had particularly stringent demands for the specific system design. From a fully automated 3-in-1 solution for the coating of watch parts to highly complex coating of a wide variety of gearboxes to a fast and flexible coating, marking and labeling system for coating pipeline pipes, these examples underline Venjakob's skills in overcoming even the greatest challenges. In any industry. In any market. For any customer.

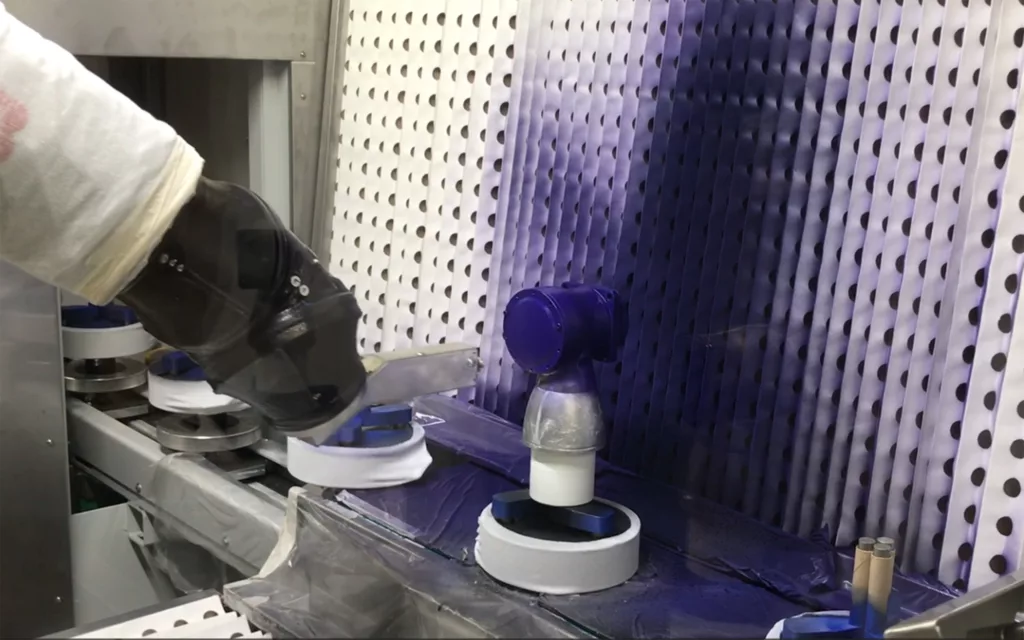

Robot coating system with automatic conversion

Fully automatic coating of highly varied gear parts – that was what Wittenstein, a globally active full-range supplier of mechatronic drive technology, requested from us. The customer required the robotic coating system to allow processing of batch size 1 as well as automatic conversion to different gear parts. As you can see, this was quite a challenging task, which we at Venjakob solved with a comprehensive plant design. The controls and mechanical system complement each other perfectly. The switch from manual to fully automatic coating went smoothly. Automatic conversion to up to 15 gear types – two to seven sizes per type – is possible at the push of a button. Production runs in two shifts and delivers stable, reproducible coating results. We even successfully reduced coating material consumption through a combination of different measures.

Coating pipe couplings with a coating, marking and labeling system

Short distances and maximum efficiency were the requests of OMK Vyksa for the coating process in its newly built pipe coupling production line. Speed and flexibility were additional criteria required from Venjakob’s coating systems. Today, the company uses two fully automated Venjakob coating lines in the manufacturing process of its pipe couplings. This complex system solution meets all required criteria for quick and flexible labeling, marking and coating of pipe couplings and fits seamlessly into the automated production process for the pipes used in pipelines. Depending on the length and diameter of the coupling, the system can coat up to 225 pieces per hour.

Compact fully automatic coating line for clock parts

Hermle Mechanische Uhrwerke und Drehteile GmbH & Co. KG is among the most cutting-edge clock factories in the world. The company is one of the last few remaining clockmakers to produce both traditional and modern wall clocks. All of their parts are made in Germany. Boasting a tradition that stretches back a hundred years, the medium-sized family company makes clocks and movements in Reichenbach am Heuberg in the German state of Baden-Württemberg. For the new plant built in 2021, Venjakob has developed a compact coating line that includes a manual spray booth for special parts, a coating line with an overhead conveyor system for coating clock frames, and a spindle chain conveyor system for coating rotationally symmetrical clock parts. It is a fully automated 3-in-1 solution.

As early as the planning stage: Tests in the technical center

In our technical center, we have the equipment to carry out tests and demo versions while still in the planning phase in order to simulate the functions of the designed process. After completing the system, the factory acceptance test can be carried out at our premises if requested.

So what’s next? Next, let’s talk – about steel coating

We would be happy to develop coating systems for almost any liquid coating material for you. Tailor-made – from stand-alone solutions to complete coating lines including surface pretreatment, drying technology and exhaust air purification system. Of course, we also take into account environmental protection and energy efficiency. Venjakob systems are unrivaled in the field of industrial coating and finishing. Simply contact us. We can expand the system concept based on your requirements, particularly in the field of steel pipe and pipe coupling coating or marking systems. Whatever you are planning, whatever you need for coating your metal and steel workpieces, we will be happy to advise you – so that you get your perfect solution.

Reference companies that use our solutions

-

TMK Group https://www.tmk-group.com

TMK Group https://www.tmk-group.com -

voestalpine https://www.voestalpine.com/group/de/

voestalpine https://www.voestalpine.com/group/de/ -

OMK Group https://omksteel.com

OMK Group https://omksteel.com -

Hermle Drehteile und Uhren https://www.hermle-reichenbach.de/Weitere-Leistungen/

Hermle Drehteile und Uhren https://www.hermle-reichenbach.de/Weitere-Leistungen/ -

Tubos Reunidos Group https://www.tubosreunidosgroup.com/en/home

Tubos Reunidos Group https://www.tubosreunidosgroup.com/en/home

Your contact

Interested? Then let's talk! About a special solution for any application – or more generally about the plant that will help you get ahead.

Gert Grosse Deters

General Industry|Automotive