- Venjakob

- Plant engineering

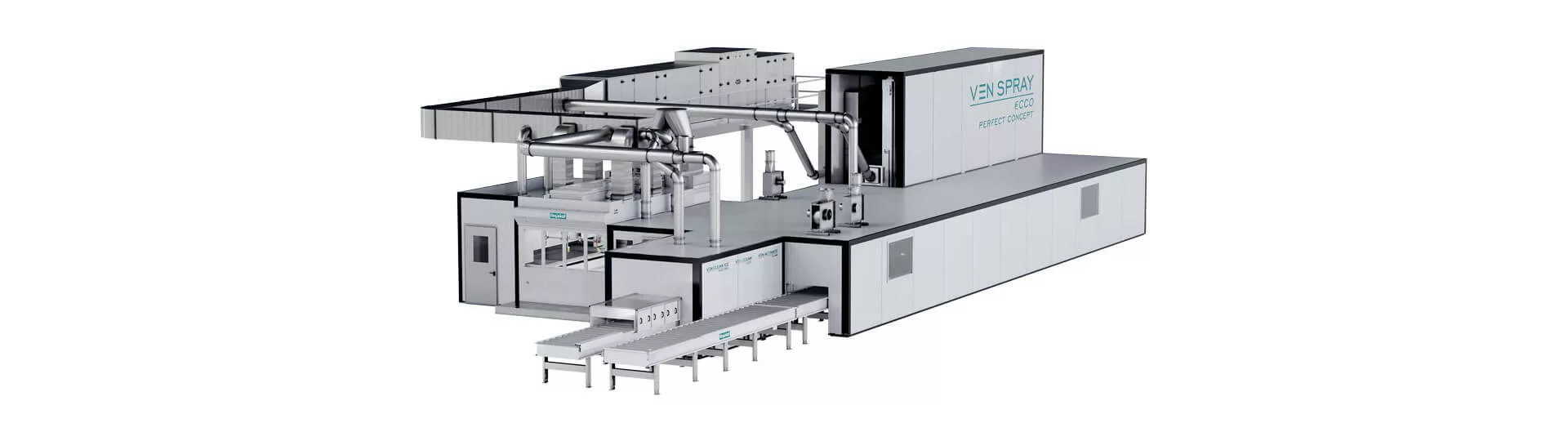

Plant engineering by Venjakob

Intelligent, innovative and individual, every time – your Venjakob system

At Venjakob, we develop and build plants in six phases: First comes consultation, followed by tests at our technical center. The next step is detailed planning and project scheduling. After production comes the big moment: commissioning. And then you’ve got it: Your Venjakob system – intelligent, innovative and individual. Why do we make a point of saying that? That’s easy to explain: Coating is an extremely complex process, which we make as simple as possible for you. And just as unique as your task, your project and your production require. What this process needs is close collaboration, coordination on details and a great deal of flexibility. And that’s exactly what we specialize in. Both in Rheda-Wiedenbrück and in Sarstedt. At these two locations, Venjakob develops and produces industrial plants and special machines according to your unique specifications in an area of more than 24,000 square meters (6 acres). With decades of experience, we guarantee that each system we produce is tailor-made.

FROM PLANNING THROUGH VISUALIZATION TO COMMISSIONING

Special machine construction requires a special perspective – and a high vertical range of manufacture

We take a very close look at what you need – and can provide it. In other words: we have a comprehensive approach to each and every task. From planning through production to commissioning at your site. We make everything ourselves that we can make ourselves. A high level of vertical integration is important to us, because it is the only way we can really ensure the quality of our systems. Among other things, this is the reason why we do most electrotechnical work ourselves. We have excellent expertise in electrical design, control cabinet prefabrication and wiring of the machines and equipment we produce. Quality assurance is one thing, production speed is another: Thanks to our in-house welding and coating facility as well as our extensive stock of various parts and construction components, we don’t just build your system completely in-house – we also reduce production times significantly and complete your order quickly.

Industry 4.0 and how we bring your plant into the digital age

A safe investment in the future – that's what your Venjakob plant represents, especially because we integrate digital solutions, from process automation through predictive maintenance to machine learning. We add digital drive to your value chain.

Always up to date in automation

We would be glad to support you with any automation issues you may have. No matter the area of application – from industrial coating through special machines to classic plant engineering: Our specially developed PLC programming is suitable for complete automation of all processes in your production line. This includes the preparation of installation, foundation and utility plans for your complete facility. We also remain by your side after the project is complete – with excellent service you can access whenever you need it. Digitally via remote maintenance – or analog and in person, if necessary.

Future-proof solutions

Intelligent, innovative, individual – this always means that we keep in mind all those aspects of development and production that are of relevance to health, social perspectives, occupational safety and the environment. Aspects like:

- Environmental protection

- Safety

- Noise and fire protection

- Immission law issues