- Venjakob

- Bonding

AUTOMATED JOINING TECHNIQUE "BONDING"

The effective solution for the automation of joining processes

Discover the new business area at Venjakob: the automation of joining processes “bonding”. Automation is one of our specialties. Benefit from our 60 years of experience in the fields of surface treatment, finishing systems and conveyor technology and us as an innovation leader in mechanical engineering. We handle the planning and realization and automat your bonding process.

Adhesive bonding applications

are nowadays an integral part of highly complex, automated manufacturing processes. In these sophisticated system concepts, not only the dispensing technology plays a central role, but also processes for pre- and post-treatment of components, quality assurance measures and the indispensable conveying and handling technology. At Venjakob, we offer holistic solutions from a single source and develop individually adapted overall solutions for automated bonding processes. Only a system that is precisely tailored to your specific requirements ensures trouble-free production and makes a significant contribution to business success.

Bonding benefits:

- Versatility: possibility of joining different materials.

- Stress distribution: uniform distribution of stresses over the entire bonding surface.

- Weight saving: reduction of weight as no additional fastening elements are required.

- Design freedom: flexibility even with complex shapes and designs.

- Corrosion resistance: ensuring longer component life.

- Temperature resistance: joined parts are not exposed to high temperatures.

- Function integration: possibility to integrate functions such as noise damping,vibration damping and sealing function.

- Cost efficiency: efficient processes for cost optimization.

- Material independence: Independent of the materials used.

- No weakening of the joined parts: ensuring the strength of the joined connection.

Your advantages with Venjakob

- Everything from a single source: A dedicated contact person accompanies you from planning and design to series production.

- Competent advice: Based on decades of experience in customer-specific special plant engineering, we offer you sound advice.

- Precise and reproducible results: Our solutions guarantee consistent quality in your manufacturing process.

- Seamless integration: Component feeding, pre-treatment and applications take place without user intervention.

- Documentable production: We offer documented production steps, especially for safety-relevant components.

- Safety technology: We integrate advanced safety technology into your systems.

- Remote maintenance: For efficient maintenance and support.

- Technical center: Our own technical center enables customer training and trials.

- Worldwide sales and service network: We are there for you globally.

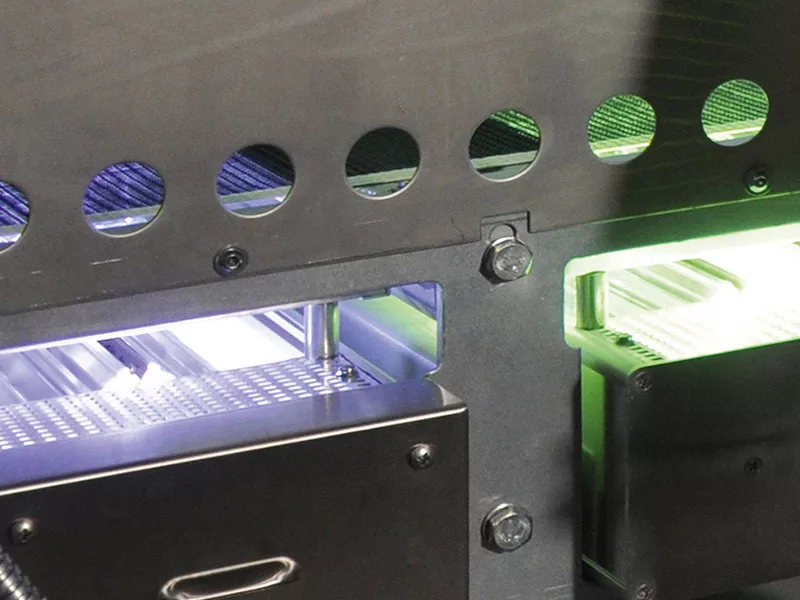

Application of the adhesive

- Application for single- and multi-component adhesives and sealants, potting compounds and foams

- Different robot and coordination systems for adhesive application

- application methods, e.g. dot. bead or spray application

- Precise adhesive application due to reproducible position of application needle, ensured by exact holder, if necessary with position control and automatic correction

Applikation des Klebers

- Auftrag für ein- und mehrkomponentige Kleb- und Dichtstoffe, Vergussmassen und Schäume

- Unterschiedliche Roboter- und Koordinatensysteme für die Klebstoffapplikation

- Auftragsarten, z. B. Punk,- Raupen oder Sprühauftrag

- Präziser Klebstoffauftrag durch reproduzierbare Position der Applikationsnadel, sichergestellt durch exakte Halterung, ggf. mit Positionskontrolle und automatischer Korrektur

Subsequent processes

- Curing systems: Infrared, ultraviolet, continuous oven, buffer line

- Quality assurance: volume measuring systems, control of material application (position and quality), component control inspection and measurement

- Process data filling and process visualization

Long-term investment security through Venjakob plant technology

Venjakob’s modular system also allows the existing system technology to be flexibly adapted and retrofitted to new conditions and requirements at a later date. You benefit from long-term planning and investment security and transparent pricing.

At Venjakob, we focus on innovation, precision and quality to optimize your manufacturing processes and meet your requirements. Contact us today to learn more about our customized solutions!

Your Contact partner