- Venjakob

- Surface pretreatment

- Cleaning process

- CO2 dry ice blasting

Dry ice blasting / snow blasting with the Venjakob CO2 cleaning system

You know the drill: Whether metal, plastic, glass, ceramics or building materials – before you coat a surface, you have to clean it. And Venjakob’s CO2 dry ice blasting systems provide the perfect way of doing so. This dry ice cleaning system is available as a stand-alone solution on request. Or – and this is the solution we at Venjakob recommend to all our customers – you integrate it into your existing processes. But no matter whether you use this method upstream or as a stand-alone solution, dry ice blasting/snow blasting cleans your workpieces without leaving residues, thereby creating the crucial conditions for problem-free coating. Read more to find out how this process works.

CO2 blasting – our solution for your cleaning problem

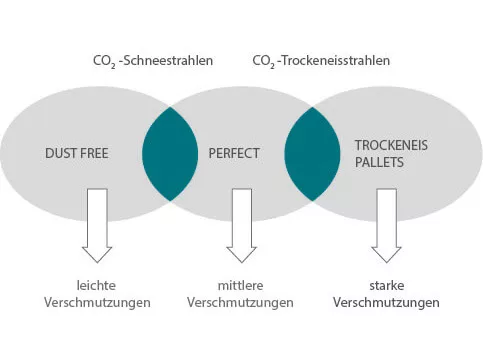

Industrial finishes almost always require surface pretreatment. This may involve abrasive processes, activation processes or the aforementioned surface cleaning. Even CO2 blasting is just one cleaning method among many. Venjakob also offers dust removal processes with additional ionization or aqueous alkaline cleaning. Each of these processes has its specific field of application. But sometimes nothing beats a targeted dry ice or snow blast. Especially when it comes to cleaning a three-dimensional small workpiece, or workpieces in large batches. Cleaning with dry ice has proven to be a fast, thorough, extremely efficient and cost-effective process. And on top of that it’s gentle to the workpiece. At Venjakob, we generally offer two methods depending on the degree of contamination: CO2 snow blasting for light to medium contamination and CO2 dry ice blasting for medium to heavy contamination.

What are the applications of CO2 dry ice blasting/snow blasting?

In general, cleaning with CO2 dry ice blasting/snow blasting has proven successful in many industries. In fact, the process is used in sectors that differ from each other a lot. This cleaning process is also an integral part of complex coating processes that take a comprehensive view of professional surface treatment. This is where Venjakob leads the way.

Areas of application

Customers often ask us: What can you blast with dry ice anyway? In principle, our blasting systems are suitable for any application. In particular, they are used in coating systems for

- Metal: From sheets and plates to sectional steel and pipes. Here you can learn more about finishing systems for surface treatment of metal and steel.

- Plastic: For products such as small and large home appliances, entertainment electronics, automotive interiors or household technology. Click here for more information about advanced surface technology for plastics.

- Glass / ceramics: For example, in the production of architectural glass, solar panels or glass in the residential sector. Find out more about this under gentle and reliable glass coating.

- Building materials: For example, for facade cladding. For efficient, customized solutions, check out our tailor-made coating systems for building materials.

Operating principle of CO2 cleaning

The two variants of CO2 cleaning - snow blasting and dry ice blasting - cover the entire range from light through medium to heavy contamination.

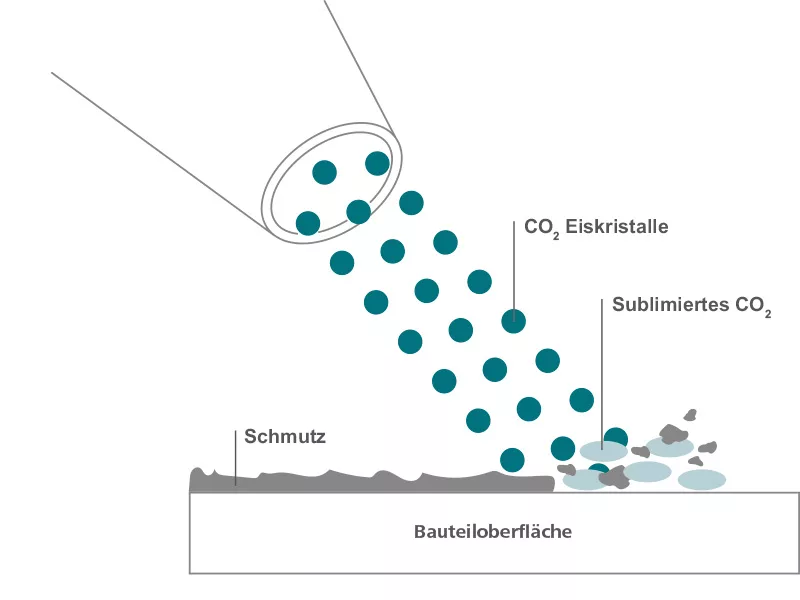

In dry ice blasting, the pellets hit the layer that you wish to remove under high pressure, freezing the dirt on the component surface and breaking it up. A process called sublimation turns the crystals gaseous, thereby increasing their volume and intensifying the effect of the compressed air: the dirt is literally blasted away.

CO2 dry ice blasting process at a glance

Dry ice blasting uses solid carbon dioxide, known as dry ice, as the blasting medium. The operating principle of dry ice blasting is comparable to abrasive blasting or high pressure water blasting. Instead of water, sand or other abrasives, solid CO2 pellets, that is, solid carbon dioxide, often referred to as "dry ice pellets", are used. The cleaning blast, consisting of a mixture of compressed air and dry ice particles, hits the surface being cleaned at high speed. To be specific, liquid carbon dioxide is frozen at a temperature of just under -80°C (-112°F) and blasted at the surfaces under high pressure in the form of pellets that are about 3 millimeters (0.1 inches) in size. The contaminants cool down dramatically, causing cracks to form in the dirt and the contaminants to become brittle, break open and detach from the surface about to be coated. This cleaning method combines ice, cold temperatures and compressed air in a way that is gentle to the machines and surfaces.

CO2 snow blasting process

The snow blasting method is an alternative that can be used for less stubborn dirt or contamination. In terms of quality, snow blasting is somewhere between CO2 dry ice cleaning and high-performance dust removal. Combined with sound protection measures and a simple mechanism to hold workpieces in place, this system variant represents a very good pretreatment method. A cold burner produces its own dry ice from liquid CO2. The cleaning blast consists of a mixture of

- CO2 snow particles

- CO2 gas that is not converted into particles

- Compressed air

Advantages and features of Venjakob CO2 cleaning systems

CO2 dry ice blasting/snow blasting from Venjakob offers many benefits. We have listed the most important ones here.

- The cleaning intensity can be adapted to the process.

Snow blasting or dry ice blasting – you decide which method is right for you.

- Applications from manual to fully automatic

What is essential is what is best suited to your production line.

- Suitable for cleaning large areas before the coating or glue application process

From small parts to large workpieces in large batch sizes.

- Can be installed on flat surfaces or in robot systems

As mentioned before: available as a stand-alone solution or for integration in your line. If you need dry ice blasting equipment, we’ll fit it in.

- Suitable for flexible integration into existing plants

See above. Because this is one of our core areas of expertise.

- Process-safe continuous operation

If you need it, it will run, and it will keep running as long as you need it. That is precisely what your plant is designed for.

- Defined CO2 consumption through permanently installed CO2 volume regulation

We keep an eye on your entire process at all times. Volume control is a firm component of cleaning with CO2. At least for us.

- Wear-free and ice-proof.

It runs and runs and keeps on running. And cleans gently, quickly and efficiently.

- Without condensate formation.

That’s because there’s nothing that could form condensate. No residue of moisture or water is left behind. For you, this means: less time spent cleaning and greater reliability.

- Cycle operation is possible due to short switch-on and switch-off times

For optimum productivity.

- Small space requirement.

We will always find a solution. Even for the smallest of spaces.

- The cleaning intensity can be adapted to the process. Snow blasting or dry ice blasting - you decide which process is right for you.

- Possible applications from manual to fully automatic The decisive factor is what is better suited to your production line.

- Suitable for large-area cleaning before the painting or gluing process From small parts to large workpieces in large batch sizes.

- Can be installed on surfaces or robot systems As already mentioned: available as a stand-alone solution and can be integrated into your line. If you need a dry ice blasting system, we can bring it in.

- Can be flexibly integrated into existing system technologies See above Because this is precisely one of our core competencies.

- Reliable continuous operation Sure, if you need it and as long as you need it, it will run. This is exactly what the system is designed for.

- Defined CO2 consumption thanks to permanently installed CO2 volume regulation We always keep an eye on your entire process. When it comes to cleaning with CO2, volume regulation is naturally part of the process. At least for us.

- Wear-free and ice-proof It runs and runs and runs. And cleans gently, quickly and efficiently.

- No condensation Nothing condenses. No moisture or water residue remains. For you, this means less cleaning work and more safety.

- Cycle operation possible thanks to short switch-on and switch-off times For optimum productivity.

- Little space required. We are sure to find a solution. Even in the smallest of spaces.

Before a system is put to use, it is tested: at our technical center

Every requirement profile is different. That is exactly why we develop customized solutions. Above all, that means one thing: collaboration based on mutual trust. You should know: We know our business. And yours. We know how to handle any matter related to optimizing coating and finishing. The same applies to the entire upstream process from feeding to pretreatment and preheating. We are also experts in the downstream drying process. In short: We keep the entire process in mind at all times. In a final step – before fully implementing our customized solutions – we test the process under realistic conditions at our own technical center in Rheda-Wiedenbrück. That includes your solution! You can learn more about this by contacting us.

In conclusion: Dry ice blasting is highly effective

If you are still wondering how good dry ice blasting really is, rest assured: It is a very good process. An extremely effective one. It is CO2-neutral and environmentally friendly to boot. This cleaning method combines ice, cold temperatures and CO2 to create a process that always pays off for industrial customers and the end users of their products. This dry ice cleaning process perfectly removes contaminants from almost any surface. There’s yet another positive side effect when the pellets hit the surface: the dry ice returns directly to a gaseous state, expanding to a multiple of its original volume and reinforcing the effect of the compressed air through this expansion. Any dirt and contaminants are practically blasted off the surface. And as the abrasive simply evaporates, you don’t have to deal with disposal. Only the dirt and contaminants detached from the surface have to be disposed of.

Your contact

Our in-house technical center makes it possible to test processes under realistic conditions. Simply tell us what you need, get your material supplier involved, and we will develop a solution together with you.

Gert Grosse Deters

General Industry|Automotive