- Venjakob

- Surface coating

Surface coating with Venjakob

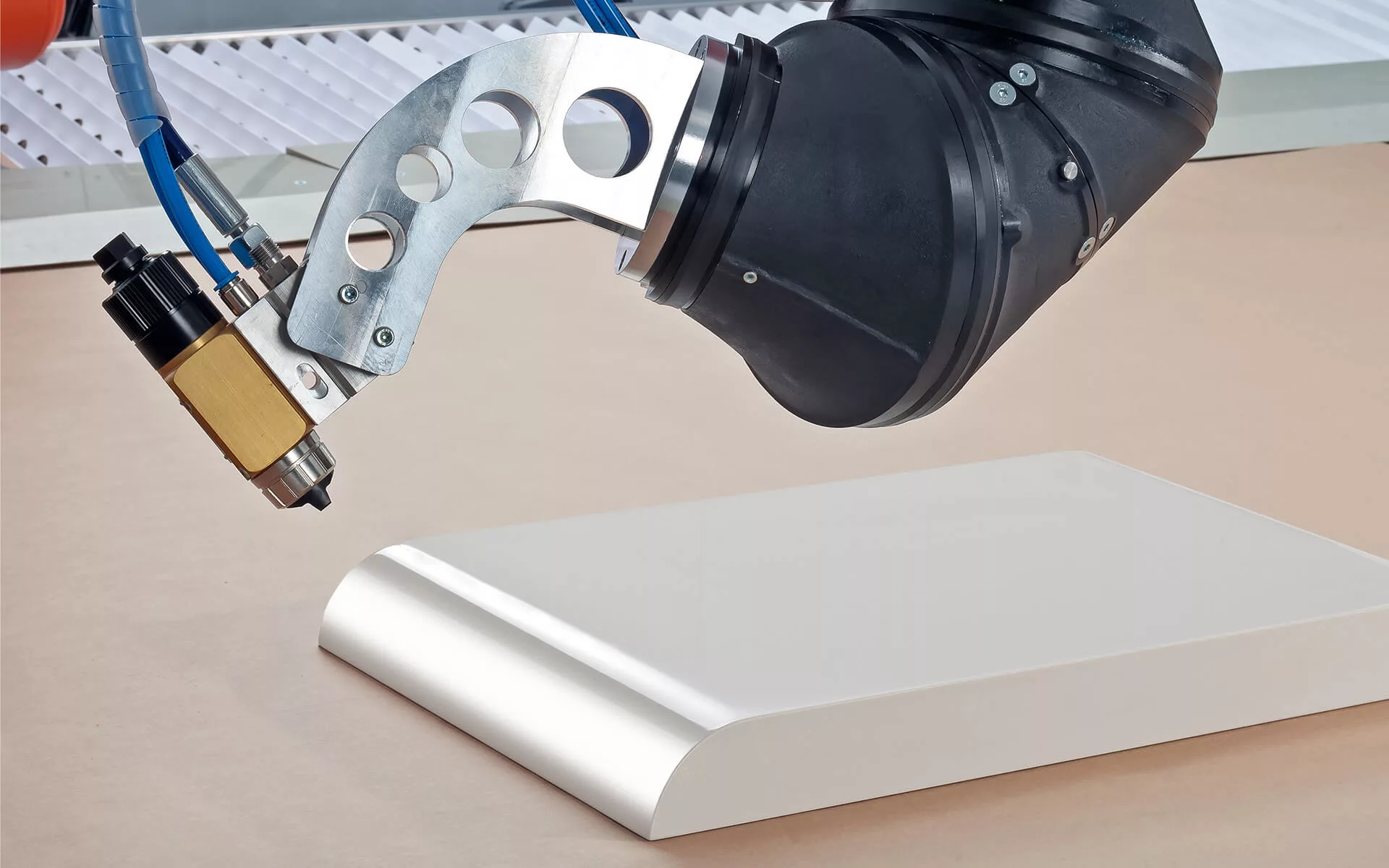

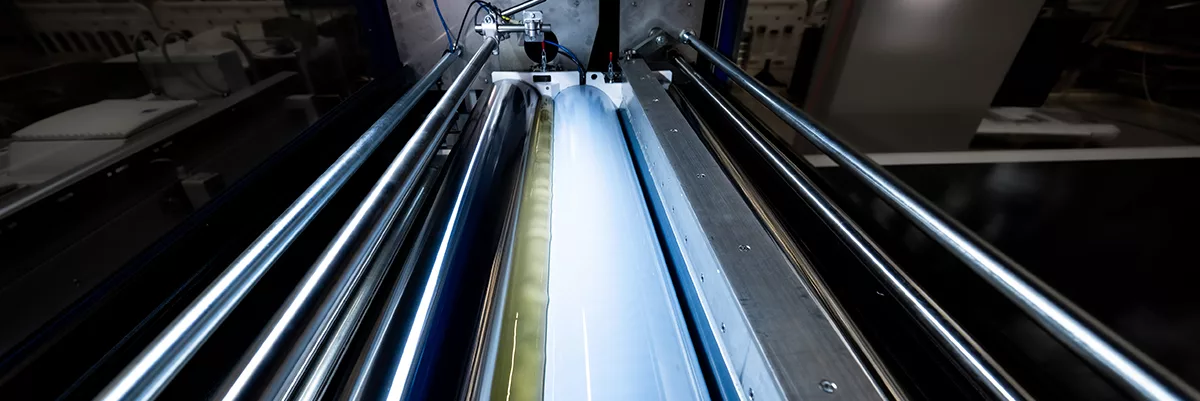

Surface coating isn’t just one thing. Even the common main categories – gaseous, liquid, dissolved or solid – each contain many different processes, which in turn can be broken down into countless variants. Surface coating – or surface technology – is a science in and of itself. At Venjakob, we prefer to take a very practical approach and focus on four methods: Spray coating, dip coating, flow coating and roller coating. For each of these processes we offer tailor-made designs that are based on the specific requirements of our customers. The processes are integrated into comprehensive system concepts that cover the entire procedure, from feeding through surface pretreatment prior to surface coating to drying and final packaging afterwards. We create customized modules, many of which are also available as stand-alone solutions. What is essential for our customers is that they can determine the extent of our services themselves. And our customers can be confident that Venjakob does not view surface technology in isolation, but adapts it precisely to the specific coating task.

The reason for surface coating

At its core, it’s all quite simple. Every surface is, first and foremost, made from the material of a specific workpiece, a specific product. Each product can consist of very different materials. The material in question may be ideal for manufacturing this product, but it is usually itself susceptible to environmental conditions. Metals, for example, may be particularly suitable for the automotive sector, but they are susceptible to corrosion. That is why they need a surface coating to protect them against corrosion. Kitchen furniture may be made of wood, but it is usually only scratch-resistant and wear-resistant thanks to a suitable coating. However, not every effective functional coating is also aesthetically pleasing. Meaning: Coatings are not just used for functional reasons, but also for aesthetic ones. Sometimes they are even purely decorative. Coatings therefore don’t just contribute to maintaining the value of a product, they can also increase its value. It all depends on which coating type and which coating process is used. But what processes are there and which do you use when?

The different coating processes

Surface coating isn’t just one thing. Even the common main categories – gaseous, liquid or solid – each contain many different processes, which in turn can be broken down into countless variants. Surface coating – or surface technology – is a science in and of itself. At Venjakob, we prefer to take a very practical approach and focus on four processes: Spray coating, dip coating & flow coating and roller coating. For each of these processes we offer tailor-made designs that are based on the specific requirements of our customers. The processes are integrated into comprehensive system concepts that cover the entire procedure, from feeding through surface pretreatment prior to surface coating to drying and final packaging afterwards. We create customized modules, many of which are also available as stand-alone solutions. What is essential for our customers is that they can determine the extent of our services themselves. And our customers can be confident that Venjakob does not view surface technology in isolation, but adapts it precisely to the specific coating task.

What we mean by coating at Venjakob

If your approach is one of customization and you consider all aspects of a coating in relation to a specific coating task – like we do at Venjakob – you will always keep the entire systematic structure in mind, layer by layer. So surface coating means not just the coating step itself, but also the surface pretreatment that precedes the finishing, flow coating, dip coating or roller coating step. The different substrates being coated are all characterized by specific properties that also affect the methods used for surface pretreatment. The applied pretreatment in turn is crucial for the quality of the coating. That’s because it creates the conditions for perfect coating adherence, perfect coating effect and perfect coating function.

How to get your surface coating

That’s easy! Get in touch with us. Let's talk about your production and how we can support you with a coating system designed just for you. What may sound complicated in this description quickly becomes very concrete in our consultation. Questions about which coating processes are available, why surfaces require coating, what a surface coating actually consists of – which different layers, which pretreatments – all these questions can usually be answered quickly in a personal conversation. There are no barriers to overcome at this point, because you know what you want – and we know how we can best support you with our process experience. The really interesting questions usually arise in the finer details of the process design: What quantities need to be handled? Which coatings in how many colors have to be applied to what and how quickly? Are we talking about mass production or single pieces? What form of automation is possible? What form of drying is required? And how do we purify the exhaust air? It is these things that make each and every project so interesting. As you can see, at Venjakob we don’t stay at surface level when talking about surface treatment.

Good to know

If you would like to learn more about our expertise before you contact us, we have provided some details under the following keywords:

Applications for Venjakob surface coating

Likely one of the most interesting sections for you is our Areas of application. This is where we offer you an overview of all the industries in which our systems are used. From wood/furniture, glass, plastic and metal through solutions for the building materials industry, for construction elements and for automotive and aerospace, to special solutions, truly everything is included. Just take a look – or better yet: Give us a call. Let’s make an appointment right away. After all: Reading is good, talking is better. And doing is best. At least that’s what we think at Venjakob.

Your contact

Contact us now for a personal consultation regarding your spray booth!

Gert Grosse Deters

General Industry|Automotive

Christian Streit

Wood|Building Materials