- Venjakob

- Areas of application

- Aerospace

Systems for the aerospace industry from Venjakob

Developed for the toughest standards

A highly specialized industry demands forward-looking technology. The aerospace industry still has the most stringent quality requirements. At Venjakob, we meet them. After all, all the components used by this industry must withstand sky-high strain – literally! That’s exactly what we are prepared to guarantee. We always adapt to our customers’ specific demands. No matter how high they are – no matter what height they are for. We keep an eye on everything – across all processes.

Process variants

- Workpiece production

- Workpiece pretreatment

- Workpiece finishing

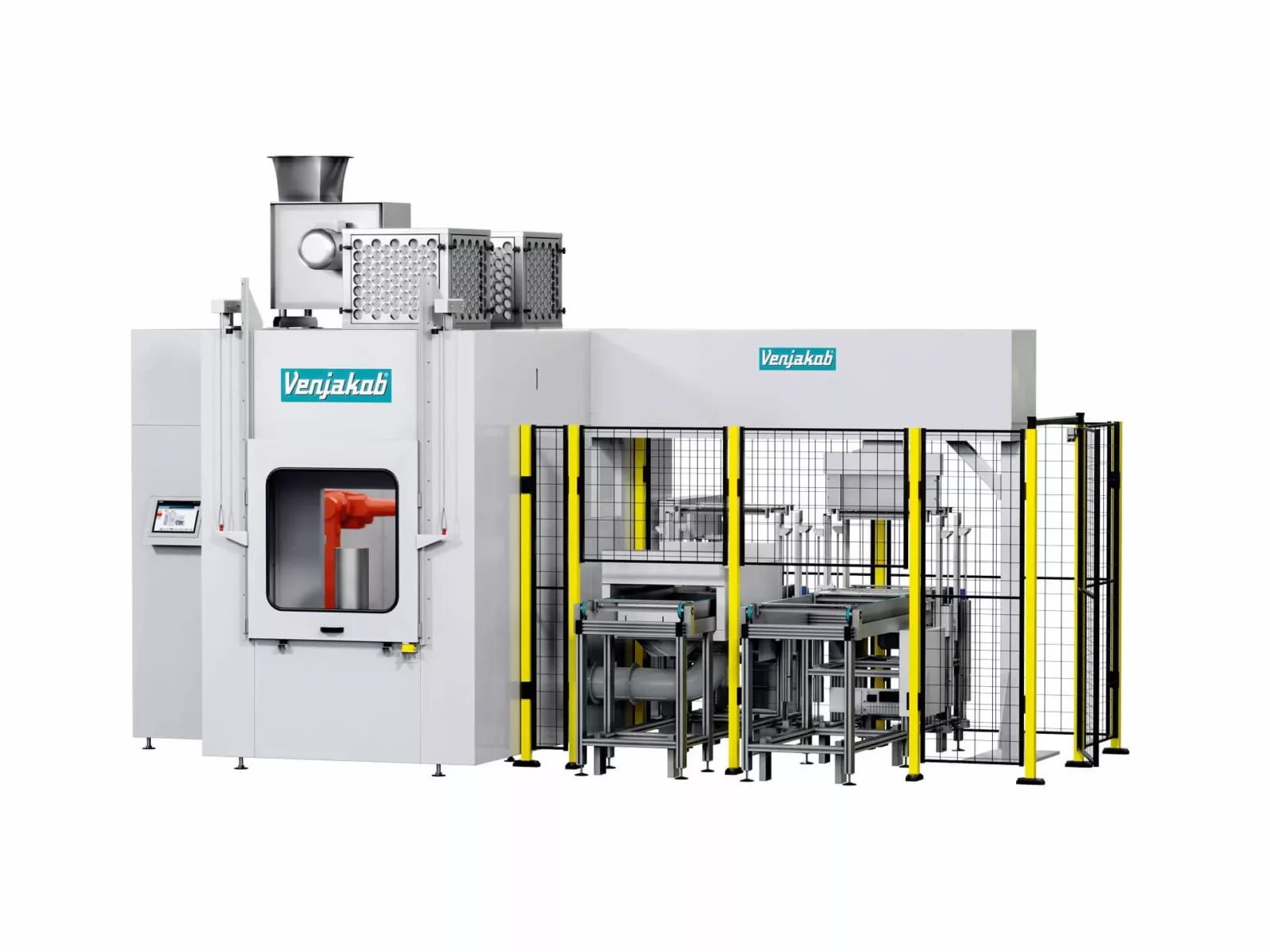

State-of-the-art, efficient, tailor-made – finishing systems for your production

At Venjakob, we support manufacturers and suppliers of components for the aerospace industry by providing customized system components. Our coating and finishing systems apply lacquers as well as composite materials and adhesives to individual workpieces made of a wide variety of materials. And they are designed to be integrated – fully flexibly – into complex production processes. They are tailored precisely to your requirements. Whether you’re producing interior parts, structural elements made of aluminum or connecting elements. Our systems are just as precisely developed for the requirements of the aerospace industry as for all other applications in industrial coating and finishing.

Applications

The interior of aircraft cabins contains numerous cladding elements that require finishing with special coatings and textured finishes. These finishes are designed to increase the durability and scratch resistance of the components. Venjakob supplies the systems to achieve this – with particularly material-friendly and efficient application processes that produce results of flawless quality.

Structural parts

Up in the air, corrosion protection on sheet metal and milled parts made of aluminum is absolutely indispensable. Venjakob helps you achieve these standards - with equipment for water-based and solvent-based coating systems.

Interiors

Interiors have to be scratch-proof and resistant - Venjakob supplies equipment for the application of textured finishes to cladding and flap elements.

Success story

A multi-purpose coating system for Aero-Coating

Aero-Coating is a contract coating service provider. For the first time ever, the company is now making use of robot-based coating with a multi-purpose coating solution from Venjakob. And it has been a great success! The special 2-in-1 robot application solution allows Aero-Coating to coat screw threads of different sizes and other components in large quantities as well as flat 3-D and rotationally symmetrical components in small batches. The system ensures uniform coating and complies with all relevant standards. “By using the robot we can now cover the 30 percent increase in customer demand and have reduced our processing times by 20 percent,” says Dr.-Ing. Florian Gehrig, Director of Aero-Coating GmbH.

From surface pretreatment to the final finish – the full process

Coating and finishing components for the aerospace industry requires intensive workpiece pretreatment. Venjakob offers a wide range of innovative equipment for surface pretreatment for this industry. These are the foundation for applying high-quality finishes in subsequent steps. And what is true for aerospace is also relevant for the automotive industry. Venjakob finishing systems for the automotive industry guarantee manufacturers first-class finishing results for any conceivable workpiece, both in the automotive interior and for body parts. Discover the other applications of our coating and finishing systems.

Your CONTACT

Interested? Then let's talk! About your customized coating solution for aerospace components.

Gert Grosse Deters

General Industry|Automotive