- Venjakob

- Surface pretreatment

- Cleaning process

- Aqueous alkaline cleaning

Aqueous alkaline cleaning systems from Venjakob

Aqueous, alkaline, effective – for particularly stubborn contaminants

Dirt on workpieces can be pretty stubborn. And it can significantly impair the coating process. It is precisely for this type of contamination – organic or inorganic residues that are difficult to remove – that Venjakob offers aqueous cleaning systems for intermediate and final cleaning of workpieces. They are operated with alkaline, neutral or acidic cleaning fluids and are mainly used when a very high cleaning volume has to be handled or for tasks in fine and ultra-fine cleaning.

When is it worthwhile to invest in aqueous alkaline cleaning equipment?

As we previously mentioned: It is the organic and inorganic residues on the workpieces that impair proper adhesion of the coating. In the worst case, the surface result is uneven or the coating might even flake off. The essential factor in determining whether investing in an aqueous alkaline cleaning system would pay off for you is therefore which and how many workpieces you coat – and what material they are made of. Metal workpieces are usually contaminated by coolant residues or greases (synthetic or mineral oil-based) resulting from mechanical processing. In addition there are other contaminants such as dust and the like, depending on the manufacturing process. If this sounds familiar from your production, then an alkaline cleaning system is perfect for you – but before we get to that, we recommend a detailed consultation. From us, Venjakob.

How does organic and inorganic contamination occur?

Metal workpieces are contaminated by coolant residues or greases (synthetic or mineral oil-based) resulting from mechanical processing. In addition there are other contaminants such as dust and the like, depending on the manufacturing process. If this sounds familiar from your production, then an aqueous alkaline cleaning system is perfect for you – but before we get to that, we recommend a detailed consultation. From us, Venjakob.

Greases, oils, waxes – areas of application for alkaline cleaning systems

Venjakob offers an aqueous alkaline-based cleaning system for surface cleaning in the metalworking industry. This method removes organic contamination such as greases, oils and waxes as well as inorganic residues such as metal chips and dirt.

Alkaline cleaners

- Dissolve inorganic contaminants such as abraded metal particles, pigments and dust

- Effectively remove metallic surface oxides such as rust and loose scale

Tailor-made, powerful and reliable – the advantages

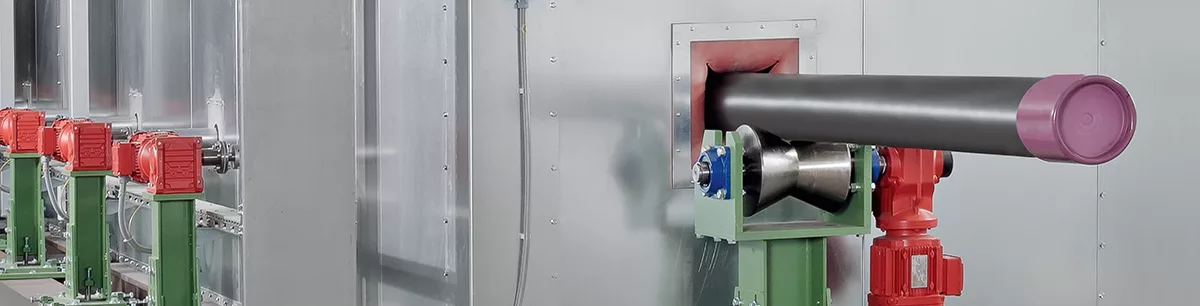

Venjakob offers you custom-designed solutions for continuous flow systems – e.g. for pipes – or for bath cleaning systems. The plant length varies based on the throughput speed. If desired and required by you, it is also possible to combine the alkaline cleaning system with effective drying technology.

- Optimum cleaning quality

- High flexibility

- Individually adaptable to the process

Your contact

These cleaning systems are available as a stand-alone solution or upstream of coating | finishing. To keep your production flexible at all times, Venjakob also offers expansion of your existing processes at any time.

Gert Grosse Deters

General Industry|Automotive