- Venjakob

- Drying technology

- UV dryers

UV dryers from Venjakob

Intense and incredibly fast – for UV-curing coating systems or adhesives

It seems obvious: UV-curing coating systems require UV dryers. If these coating materials did not exist, these dryers would not exist either. Venjakob combines both, UV-curing coating systems and UV curing technology, in custom-designed coating lines. For your benefit. These systems require little space and reduce your production time, as UV curing takes just seconds. The number of emitters and lamps required depends on the type of substrate, the throughput speed, the applied quantity and the workpiece geometry. Whatever your production needs, Venjakob has the perfect UV dryer with conventional Ga, Hg and iron doping – or even with LED technology.

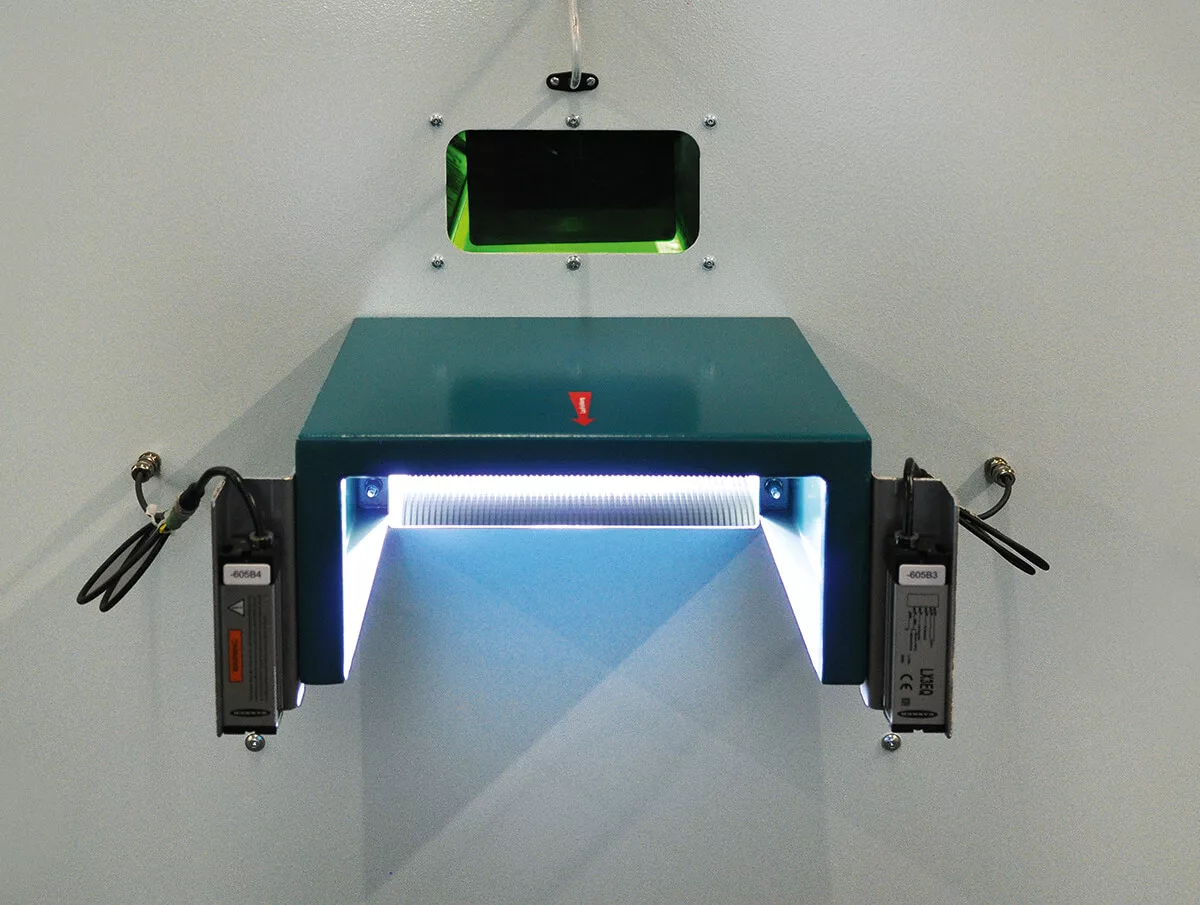

Space-saving, durable, powerful – what makes Venjakob UV dryers special

Our industrial UV dryers are designed to impress with low wear and tear and a long service life of the UV lamps. And if you do need to replace them, it’s quick and easy thanks to the modular design. But the most important thing is performance! And that’s where Venjakob UV dryers really shine: They achieve exceptionally homogeneous curing of the material surface while at the same time drying your workpieces particularly gently. Thanks to a reduction of the IR components in the UV light – referred to as a “cold mirror” – the workpiece surface heats up only slightly. This is particularly beneficial if you are processing temperature-sensitive materials. The modular design of all Venjakob systems offers you maximum flexibility. While they are designed to save space, UV modules can also be added at any time. Last, but not least: The exhaust air in our UV dryers is temperature-controlled to help you reduce your operating costs.

Sophisticated, adapted, energy-efficient – power-optimized UV lamps

The UV lamps used in our Venjakob UV dryers are power-optimized and have emission spectra that are precisely adapted to the applied coating. You have a choice of Hg, Ga or Fe-doped lamp models. LED technology is also available. Sophisticated electronic ballasts ensure safe and reliable operation.

Application examples

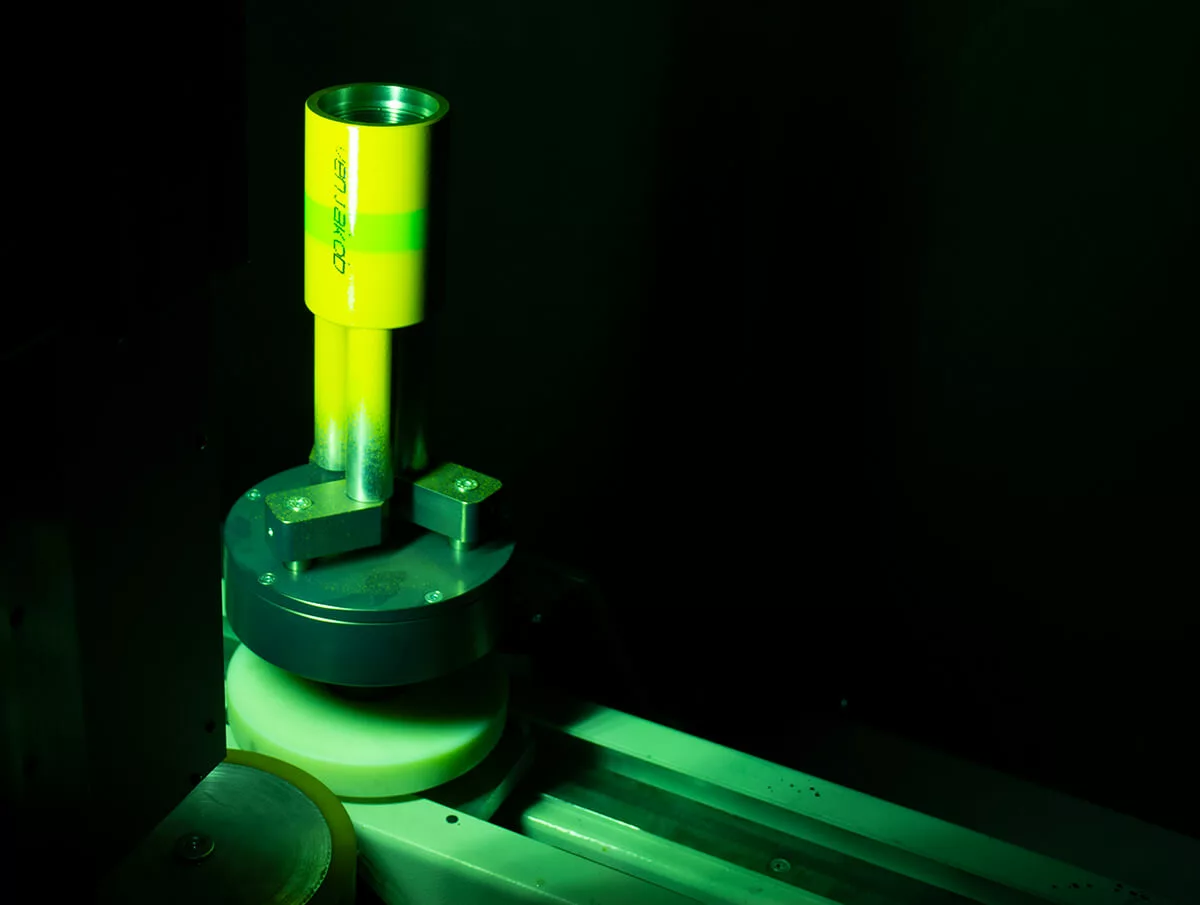

Specially developed for edge hardening – the Venjakob Surround UV technology

Edges are a very special case, for which Venjakob offers a very special solution. Our specially developed Surround UV technology with its special reflector geometry guarantees thorough hardening of the edges on your workpieces. What makes this system so unique is the arrangement of specially aligned reflectors that avoid applying direct UV radiation to the workpieces, but still provide thorough three-dimensional radiation. Despite all this, the workpiece temperature only increases very slightly. The specially developed reflectors make it possible to cure the surfaces and edges of the workpieces in a continuous process. For clear coatings, one lamp is usually sufficient, while colored coatings require only two. This is not just effective in the edge area, but highly energy-efficient in total, as this technology allows you to reduce energy consumption by 20 % and more compared with conventional methods.

Areas of application for Venjakob UV dryers

- UV coating materials such as water-based and solvent-based UV coatings, high-solid UV coatings, both colored and transparent

- Equally suitable for workpieces made of wood, plastic, glass, building material and metal

- Excimer technology (matting effect)

Advantages of UV curing technology

- Extremely short curing times

- Immediate further processing possible

- High gloss level

- High scratch resistance

- Particularly resistant to chemical stress

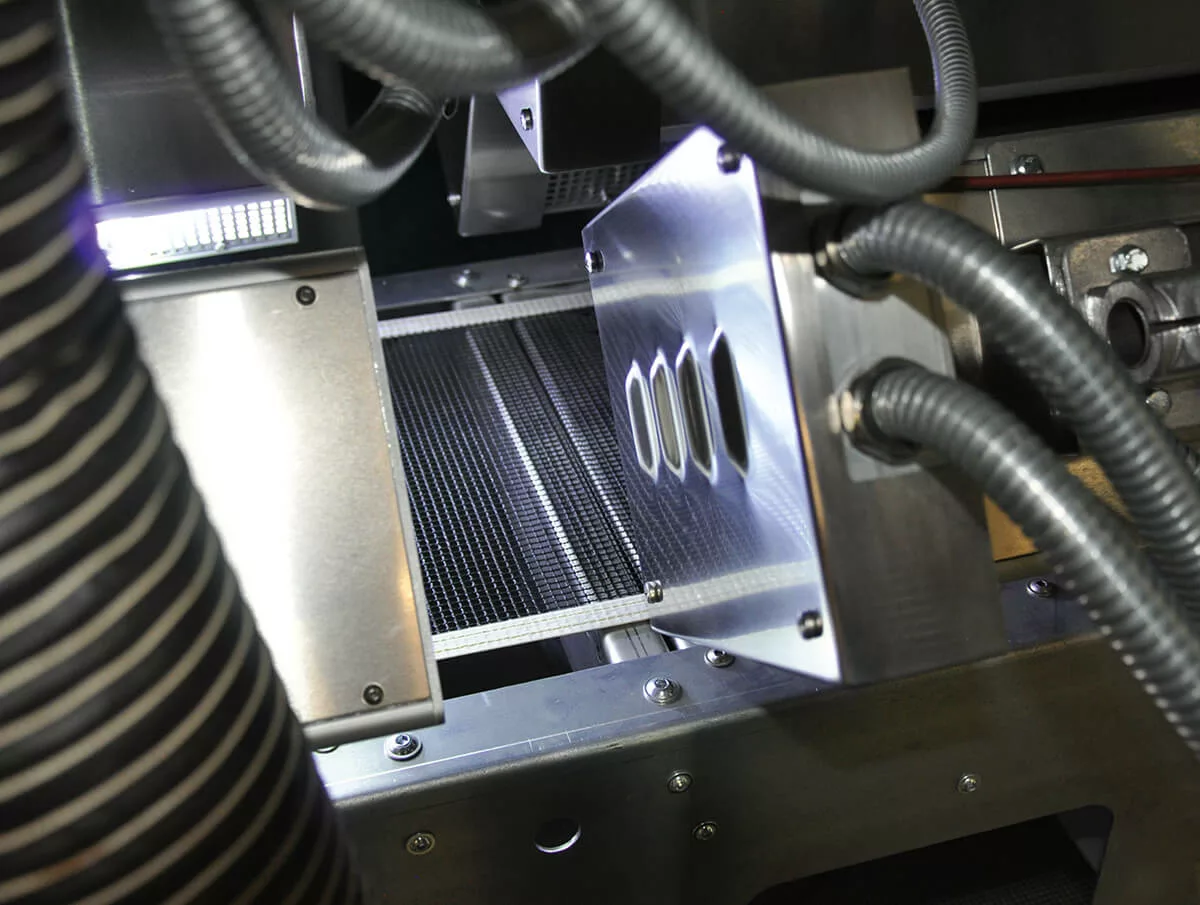

Advantages of Venjakob LED UV technology

Innovative, integrated Venjakob LED technology reduces the thermal load on the workpieces and optimizes your energy balance – including thanks to the long service life of the LED lamps. And unlike conventional UV processes, no ozone is released into the air in your building.

- No shutter required

- Lamps with a much longer service life

- No reflector required

- Considerable energy savings compared with conventional medium pressure UV systems

- Individual LED segments can be turned on and off to adjust the width control of the lamps

Your contact

Interested? Then let's talk! About your coating solution with innovative UV curing from Venjakob.

Gert Grosse Deters

General Industry|Automotive

Christian Streit

Wood|Building Materials